Views: 0 Author: MATT Publish Time: 2026-01-14 Origin: Site

Starting an eyewear brand shouldn't feel like navigating a manufacturing maze. Many aspiring brand owners face the same frustrating barriers: factories demanding minimum orders of 1,000+ units, lead times stretching beyond three months, and the terrifying prospect of warehouses filled with unsold inventory.

The traditional OEM route requires deep pockets and nerves of steel. You're expected to commit tens of thousands of dollars to frames that haven't sold a single unit yet. For new brands testing market demand or established retailers expanding their product lines, this model simply doesn't make sense.

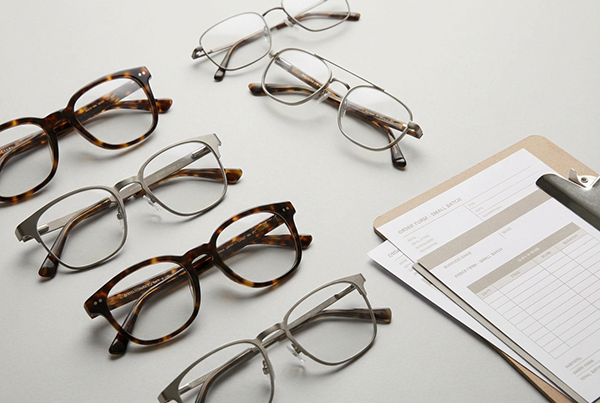

There's a smarter path forward: private label eyewear using stock frames with custom logo printing. This approach combines the branding benefits of a proprietary collection with the safety net of proven, market-tested designs. You get to market faster, test with lower risk, and scale based on actual sales data rather than hopeful projections.

The beauty of stock frame private labeling lies in its accessibility. Unlike full OEM production that often requires 500-1,000 pieces per model, stock frame programs typically start at 50-100 units per style. For new brand launches, this difference is transformative.

Consider the math: if you're testing five different styles to see what resonates with your customers, full OEM might require $15,000-$25,000 in upfront inventory. With stock frames, you could launch the same five-style collection for $3,000-$5,000. That's the difference between a calculated test and a bet-the-business gamble.

This lower entry point makes private label eyewear accessible to:

· New brand founders validating their business concept

· Online eyewear stores expanding beyond dropshipping to build margin

· Regional distributors testing new geographic markets

· Optical shops creating house brands to compete with mass-market alternatives

Nothing kills momentum like running out of your best-selling frame for three months while you wait for a new production run. Stock frames eliminate this pain point entirely.

Because these frames are already in continuous production for multiple brands, your supplier maintains steady inventory levels. When your bestseller starts flying off the shelves, you can reorder in weeks rather than months. This consistent availability allows you to:

· Maintain sales velocity without stockout interruptions

· Plan marketing campaigns confidently around product availability

· Build customer loyalty through reliable inventory

· Scale winners quickly while phasing out underperformers

The restock advantage becomes even more valuable as your brand grows. As you identify your core collection—those 3-5 styles that generate 80% of revenue—you can maintain deeper inventory levels without the cash flow strain of custom mold production.

Here's an uncomfortable truth about eyewear design: most new frame designs fail. Even experienced designers backed by major brands launch styles that never gain traction.

Stock frames offered for private label programs carry a significant advantage—they're already selling. These are designs that have proven themselves across multiple markets: Europe's fashion-forward consumers, Southeast Asia's style-conscious middle class, the Middle East's luxury-oriented buyers.

When you select from a supplier's stock frame catalog, you're essentially cherry-picking from designs that have already survived market validation. You're not gambling on untested aesthetics; you're choosing from frames with proven commercial viability.

This doesn't mean your collection will lack distinctiveness. Metal glasses frames offer timeless sophistication that appeals to professional customers, while acetate glasses frames provide bold color options and artistic patterns for fashion-forward positioning. TR90 glasses frames deliver the lightweight durability that active lifestyle customers demand. Each material category offers dozens of style variations, allowing you to curate a collection that reflects your brand identity while standing on solid commercial ground.

Your logo transforms anonymous stock frames into branded products. Understanding your printing options ensures you choose the method that aligns with your frame materials, price positioning, and brand story.

Laser engraving creates permanent, precise branding that communicates quality at first glance. The technology works by removing material from the frame surface, creating an etched effect that won't fade, peel, or wear off.

This method excels on metal glasses frames, where the contrast between polished metal and etched branding creates sophisticated visual appeal. Titanium frames particularly benefit from laser engraving—the permanent marking reinforces the premium positioning these frames command.

Best for:

· Professional and luxury brand positioning

· Metal and titanium frame collections

· Brands emphasizing durability and longevity

· Higher price point products ($50+ retail)

Considerations: Laser engraving typically appears in single-tone (the frame's base metal color). If your brand identity relies heavily on color, you'll want to explore alternative methods.

Silk screen printing offers versatility that laser engraving cannot match. This method applies ink to the frame surface, allowing for color logos, multiple colors, and larger design elements.

The technique works beautifully on acetate glasses frames and TR90 glasses frames, where the smooth plastic surfaces provide ideal canvases for detailed graphics. Fashion brands often leverage silk screen printing to incorporate colorful logos that complement their bold acetate patterns.

Best for:

· Fashion-forward brand identities

· Colored logo requirements

· Acetate and plastic frame materials

· Entry to mid-range price positioning

Considerations: While durable when properly applied, silk screen printing doesn't offer the same permanence as laser engraving. Ensure your supplier uses high-quality inks and proper curing processes.

Hot stamping creates a metallic impression on frame temples, offering a classic luxury aesthetic without the cost of precious metal inlays. The process uses heat and pressure to transfer metallic foil onto the frame surface.

This method delivers perceived value that exceeds its cost. A simple gold or silver hot-stamped logo on temple arms can elevate a mid-range frame into premium territory in customers' minds.

Best for:

· Classic and heritage brand positioning

· Temple arm branding

· Enhanced perceived value

· Both plastic and metal frames

Strategic Insight: Your logo method should align with your overall brand positioning, not just minimize costs. A premium brand launching with silk screen logos on cheap temples sends mixed messages. Conversely, laser engraving on entry-level frames might over-invest in branding relative to the product's market position.

New brand founders often obsess over custom packaging before selling their first frame. This is understandable—packaging is tangible, controllable, and seems crucial to brand perception. But it's often the wrong priority for early-stage brands.

Your first orders should focus budget and attention on the frames themselves. Stock packaging—generic cases, standard cleaning cloths, basic care instructions—keeps your initial investment low and your time-to-market fast.

This approach offers several strategic advantages:

· Lower MOQ: Custom packaging often requires higher minimums than frames

· Faster delivery: No design approval cycles or packaging production delays

· Flexibility: Easy to pivot if early customer feedback suggests different packaging needs

· Cash preservation: Invest capital in inventory that generates revenue, not boxes

Many successful eyewear brands launched with branded frames in stock packaging, then upgraded based on customer feedback and sales performance. This lean approach validates your product-market fit before investing in peripheral elements.

Once you've identified your best-selling styles and proven customer demand, custom packaging becomes a powerful value-add:

· Branded cases that serve as marketing when customers carry them

· Custom instruction cards explaining your brand story

· Premium unboxing experiences that generate social media content

· Protective packaging that reduces return rates from shipping damage

The key is sequencing: prove the product first, enhance the presentation second.

Success in private label eyewear isn't about revolutionary innovation—it's about smart sequencing and disciplined execution. Here's the framework that minimizes risk while building sustainable brand value:

Step 1: Select Best-Selling Stock Frames

Start with your supplier's proven performers. Request sales data, market feedback, and restock frequency. Choose 3-5 styles that cover different face shapes and style preferences:

· One classic metal frame for professional customers

· One bold acetate option for fashion-forward buyers

· One lightweight TR90 style for active lifestyles

· Two versatile options that appeal to broad audiences

This curated approach prevents the paralysis of too much choice while ensuring you're not betting everything on a single style.

Step 2: Apply Your Logo Strategically

Place your branding where it's visible but not overwhelming. Temple arms offer prime real estate—visible when frames are on a table, subtly present when worn. Inner temple markings provide brand authentication without dominating the design.

Choose your logo method based on frame material and brand positioning. Remember: consistency matters more than complexity. A simple, well-executed logo beats an elaborate design poorly applied.

Step 3: Order with Low MOQ

Start with 50-100 units per style. Yes, your per-unit cost will be higher than at 500+ pieces. Accept this as market research investment, not inefficiency.

The goal isn't to minimize unit cost—it's to minimize total risk while gathering customer data. Once you identify which styles sell, you'll scale those winners and phase out underperformers.

Step 4: Use Fast Restock to Scale Winners

This is where the stock frame model truly shines. When Style A sells through in six weeks while Styles B and C sit stagnant, you can immediately reorder Style A without touching dead inventory.

This data-driven approach compounds your success:

· Cash flows from sales fund reorders

· Inventory turns faster, reducing carrying costs

· You build depth in proven styles rather than breadth in untested ones

· Customer satisfaction remains high because best-sellers stay in stock

Over 6-12 months, this process naturally evolves your initial test collection into a refined, proven catalog that generates predictable revenue.

Private label eyewear through stock frames isn't theoretical—it's the model independent brands use every day to compete with established players without their capital requirements.

The path forward is straightforward: identify a supplier offering stock frames with low MOQ logo printing, select 3-5 styles that align with your brand vision, and place your first order. Your market will tell you quickly what's working.

The brands that succeed aren't those with perfect first collections—they're the ones that launch, listen, and iterate based on real customer behavior rather than assumptions.

Ready to explore stock frame options for your private label collection? Request a quote to discuss best-selling frame styles, logo printing methods, and MOQ requirements tailored to your market positioning and budget.

About Private Label Stock Frames

This guide is designed for eyewear entrepreneurs, optical retailers, and distributors seeking practical, low-risk entry into private label branding. Stock frames with custom logos offer the fastest path to market while maintaining quality and brand identity.

For more information on specific frame materials, logo printing techniques, or minimum order quantities, contact suppliers specializing in B2B eyewear solutions with private label capabilities.